Profiling and Sectioning

Rough Profiling & Sectioning by bandsawing

Valuable savings from rough profiling and sectioning.

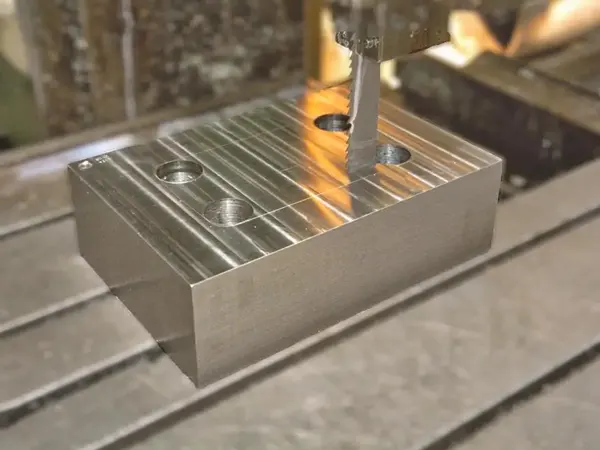

At Accurate Cutting Services, specialist heavy-duty vertical band saws produce substantial savings by profiling blanks to remove excess material in bulk – Sectioning by bandsawing.

The removal of excess material prior to machining can significantly reduce machining time and reduce tooling costs. The offcuts are available for use or for sale as prime stock, rather than scrap.

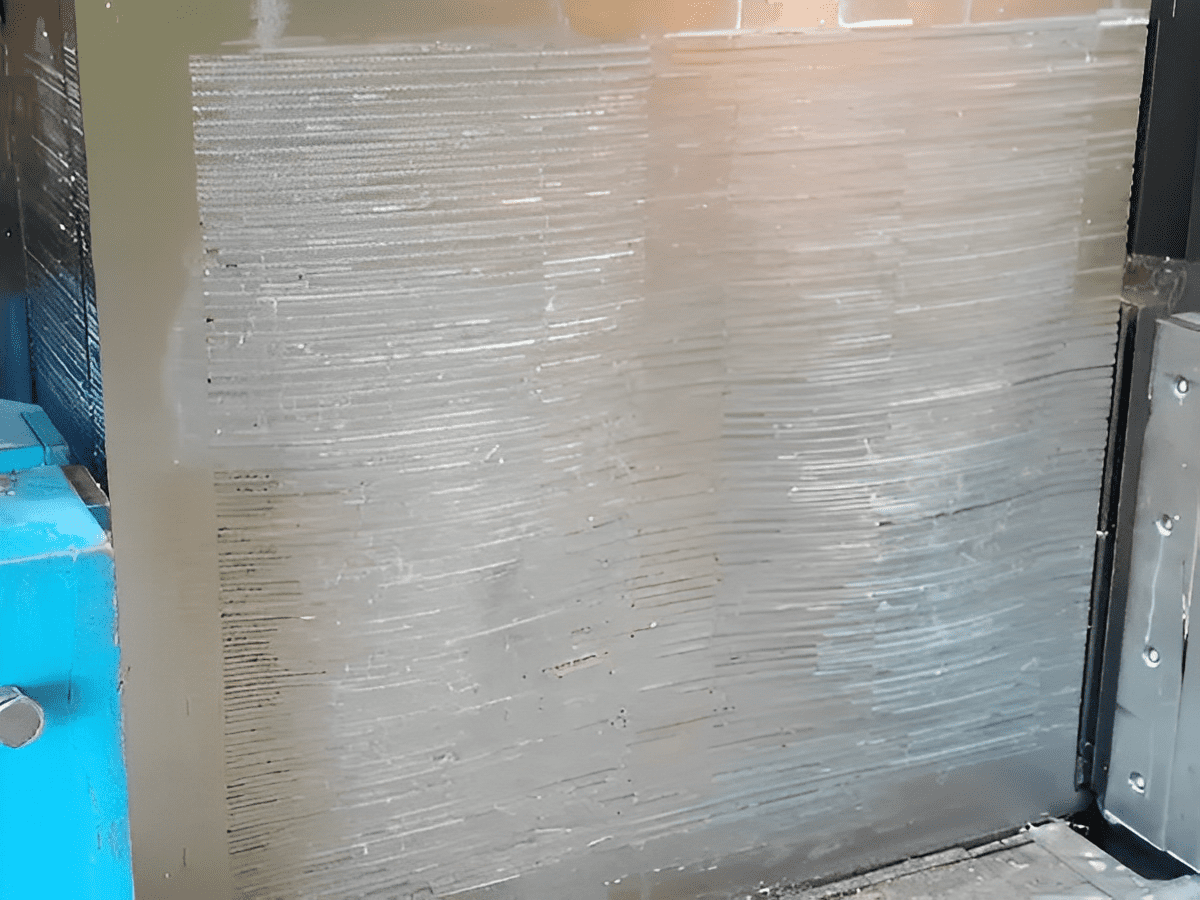

Using a band-saw blade, less material is turned into swarf or chippings, 2mm or 3mm kerf loss being typical. No heat-affected zones are created in the pieces produced, either, by this cold-cutting process.

Applications

At Accurate Cutting Services, specialist heavy-duty vertical band saws produce substantial savings by profiling blanks to remove excess material in bulk – Sectioning by bandsawing.

The removal of excess material prior to machining can significantly reduce machining time and reduce tooling costs. The offcuts are available for use or for sale as prime stock, rather than scrap.

Specialist materials, like titanium, are only available in small quantities and at great cost, and are frequently not available in an economic form. Accurate Cutting Services can cut these materials to sizes that reduce wastage in subsequent machining operations.

More informations

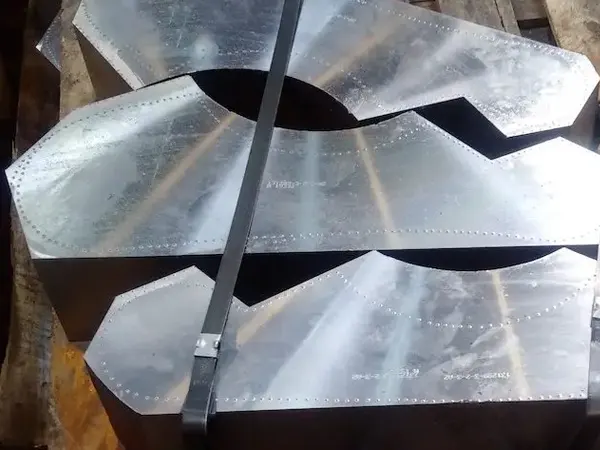

Here, the company’s customer required the cutting of four square sections from a round billet of tool steel.

The work by Accurate Cutting Services reduced the subsequent machining costs, and made the material available to the customer straight away.

The company is often asked to cut profiles in steel and non-ferrous materials. It uses its vertical band-saw machines to cavity-saw pre-drilled blocks or plate, or to cut profiles to contour-lines or drawings.

Profiles in material up to 1000mm thick (straight cuts only) can be produced, the offcuts being returned for use in other projects.