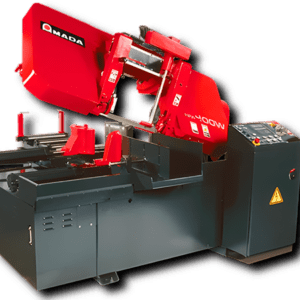

Amada HFA430CNC automatic bandsaw machine

![]()

Accurate Cutting Services is proud to announce the introduction of the new Amada HFA430cnc dynamic bandsaw.

Description

Amada HFA430cnc dynamic bandsaw

Accurate Cutting Services is proud to announce the introduction of the new Amada HFA430cnc dynamic bandsaw. This is a dynamic high performance saw featuring many new technologies. This new saw was initially presented at the EMO fair in Hannover, Germany 2013.

New Technologies

Dynamic frame

Highly rigid frame that incorporates a newly designed double guides frame (dynamic frame)

New CNC control facilitating ease of use and rapid setup

Three different cutting modes for maximum efficiency: “Eco-mode”, “Standard-mode”, and “Power-mode”

Double vibration dampening rollers

Double rollers reduce vibration resulting in faster and quieter cutting while improving blade life

New saw blade frame design results in longer blade life

By reducing the twist in the blade, fatigue is greatly reduced leading to longer blade life

High efficiency

Higher material yield by producing a material remnant as small as 35mm

Improved cleaning and capture of material chips through a cleaning device mounted on the saw (chip flusher)

The work feed table and the work tray are open-top designed and long stroke feeding vice is adapted

The machine is equipped with the function of reducing the operator’s workload during unload the work pieces (quick hoisting-function)

Video

AMADA has already achieve great success with high end models like a Pulse Cutting Band Saw (PCSAW) series, and other standard models such as the H and HS/FA series. The HFA430cnc is released as a middle of class machine, designed to give an optimised performance with a competitive price point.

Ease of Use

Automatically adjusting wire brush

Reduces adjustment time and assures accurate position of the brush

Open top, longer feed stroke vice

27 inch rear feed vice stroke length

Non-contact material positioning

Auto trim function using a laser to detect the material position results in shorter run times.

Environmental Improvements

Increase material yield by new vice

A new rear vise design reduces the remnant length to 35mm plus the length of the part improving the yield out of every bar cut.

LED work light

Amada HFA430 work illumination

New LED work light conserves energy, lasts 8x longer and provides a much brighter cutting environment.

Automatic cutting fluid supply

Automatically supplies cutting fluid only when the machine is cutting using less energy.

SMARTCUT BAND (Option)

SMARTCUT BAND (optional) saves material loss and increases yield.

Improved Working Environmental

Smart blade change feature

Blade support holder makes eases the task of changing blades

Chip flusher

More efficient chip flushing is built into the machine design to facilitate up time

Burr removal

Burrs are reduced by the unique design under the cutting area

Position the remnant into the best location

Automatically measures weight and balance of the remnant material and then positions the remnant into the best location to sling it.

Discharge table

The discharge table, too, has a retractable device allowing easier overhead material removal.

Specifications

| HFA430cnc | ||

|---|---|---|

| Cutting capacity (mm) | Round (Diameter) | 30 – 430 |

| Rectangle (W x H) | 30 – 430 | |

| Min. cut-off length | 10 | |

| Min. remnant length | 35 | |

| Blade size (W x T x L) (mm) | 41 x 1.3 x 5300 | |

| Blade speed (m/min) | 15 – 120 | |

| Motors (kW) | Blade | 5.5 |

| Hydraulic pump | 1.5 | |

| Coolant pump | 0.18 | |

| Wire brush | 0.09 | |

| Power requirement (kVA) | 13 | |

| Feeding vice stroke length (mm) | 700 | |

| Tank capacity (L) | Hydraulic | 20 |

| Coolant | 68 | |

| Table height (mm) | 700 | |

| Allowable load (Mass of work) (kg) | 3000 | |

| Machine dimensions (W x L x H) (mm) | 2520 x 2180 x 2020 | |

| Mass of machine (kg) | 3500 | |

These specifications and machinery and equipment appearance are subject to change without notice for reason of improvement.