How Accurate Cutting Can Save Costs in Large-Scale Manufacturing

For large-scale manufacturers, controlling costs is essential to maintaining a competitive edge. Precision in cutting is one area where significant cost savings can be achieved. This blog explores how accurate cutting techniques can reduce material waste, improve efficiency, and ultimately lead to cost savings in large-scale manufacturing.

Reducing Material Waste Through Precision Cutting

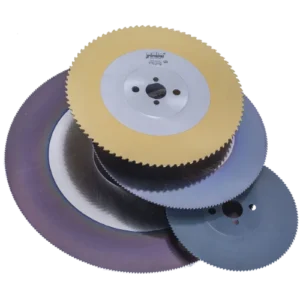

Accurate cutting ensures that materials are used to their fullest potential, reducing the amount of waste generated during production. For example, precision laser or water jet cutting can achieve extremely tight tolerances, meaning each cut is exactly where it needs to be. This accuracy not only minimises material waste but also reduces the need for rework, saving both time and money.

Improving Production Efficiency

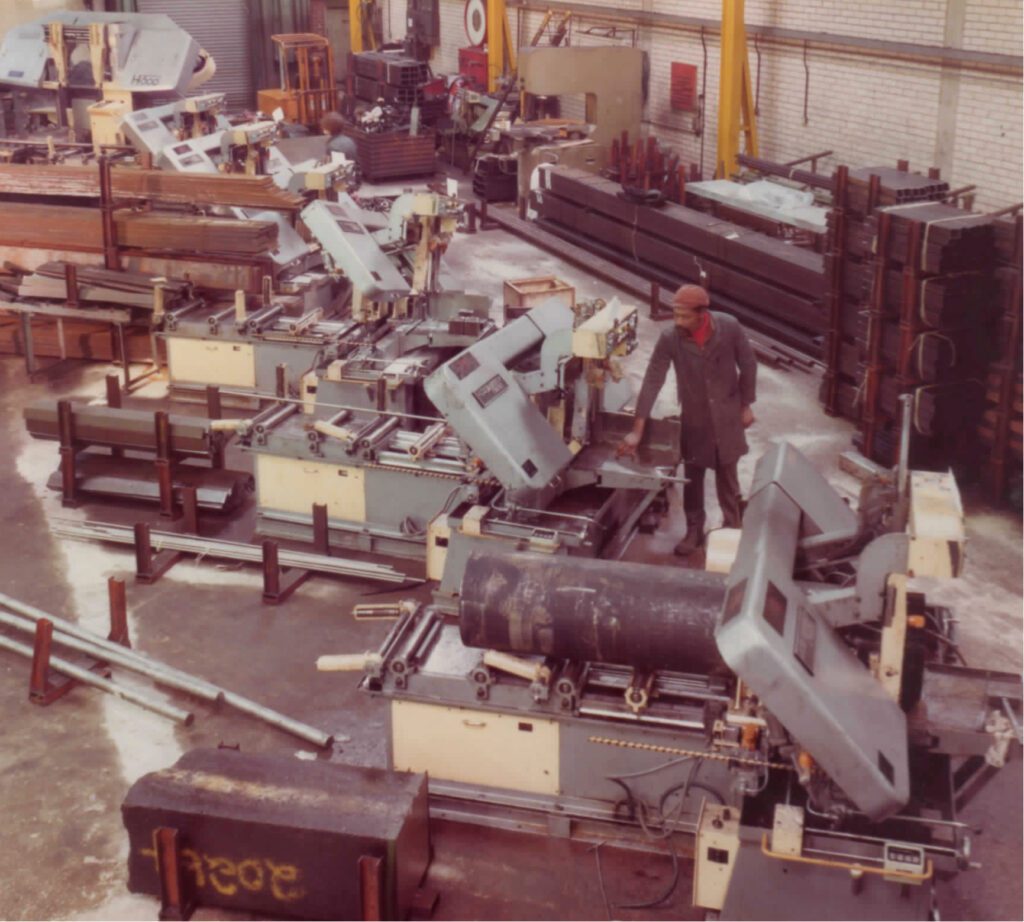

Accurate cutting techniques contribute to a more streamlined production process. With each piece cut to exact specifications, assembly and manufacturing operations can proceed more smoothly, reducing the risk of delays. In large-scale operations where time is money, these efficiencies can make a substantial difference.

Enhancing Product Quality

Precision cutting improves the overall quality of the end product. Components that are accurately cut fit together more seamlessly, reducing wear and tear and improving durability. This is especially important in industries like automotive or aerospace, where high-quality components are essential for safety and performance.

In large-scale manufacturing, accurate cutting isn’t just a matter of quality; it’s a powerful tool for reducing costs and improving operational efficiency. Manufacturers that invest in precision cutting techniques can achieve better results with fewer resources, giving them a competitive advantage.