Cutting services

We can provide sawing solutions to a wide range of cutting problems, producing results where other technologies fail.

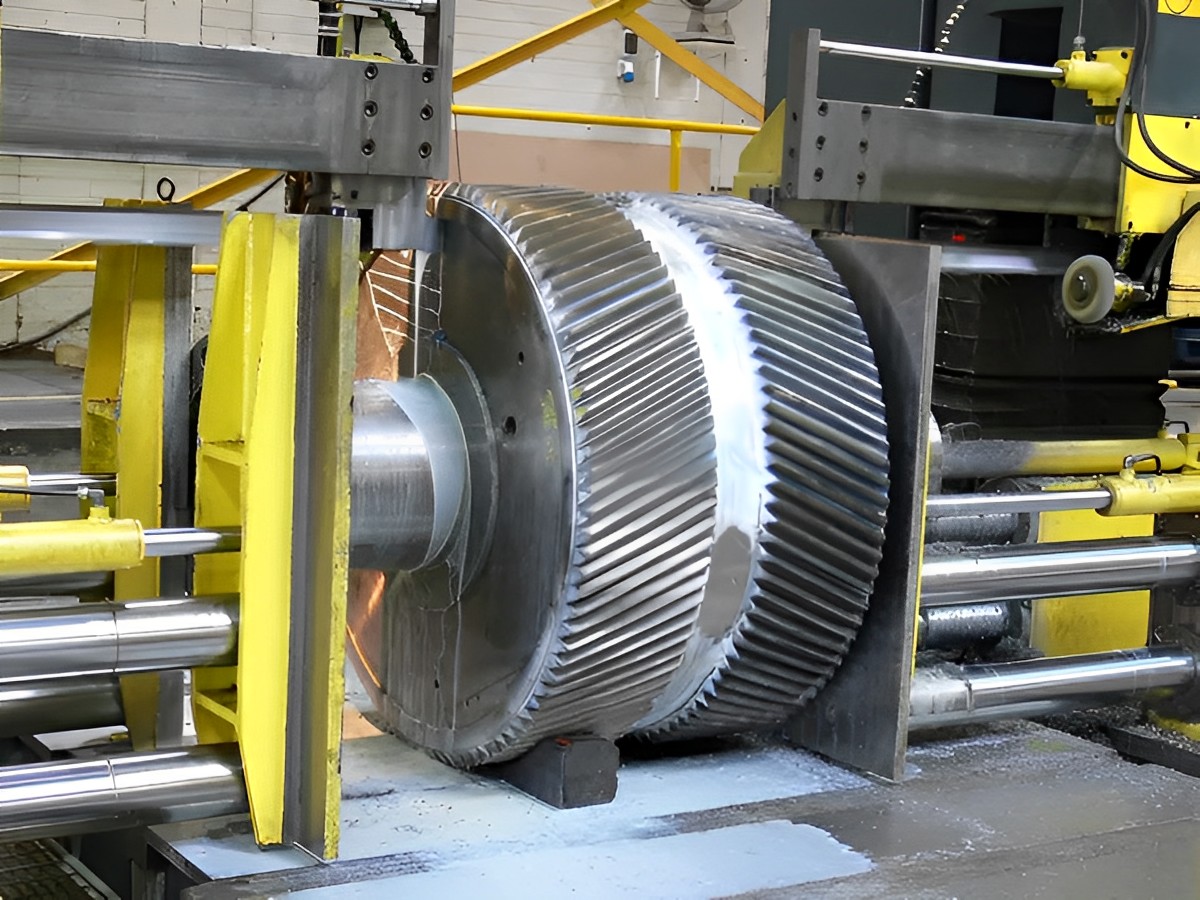

Subcontract cutting services sawing metals and non-metals in finished, part finished, rolled, cast, forged or mill form with a 25 tonne max lift capacity, 1600 x 2000mm section, 1000mm high by 6000mm long for all metals. Cutting of metal plate, bar, castings, forgings, fabrications and part machined items in stainless steel, nickel alloys, steel alloys, titanium, aluminium etc. is within our capability.

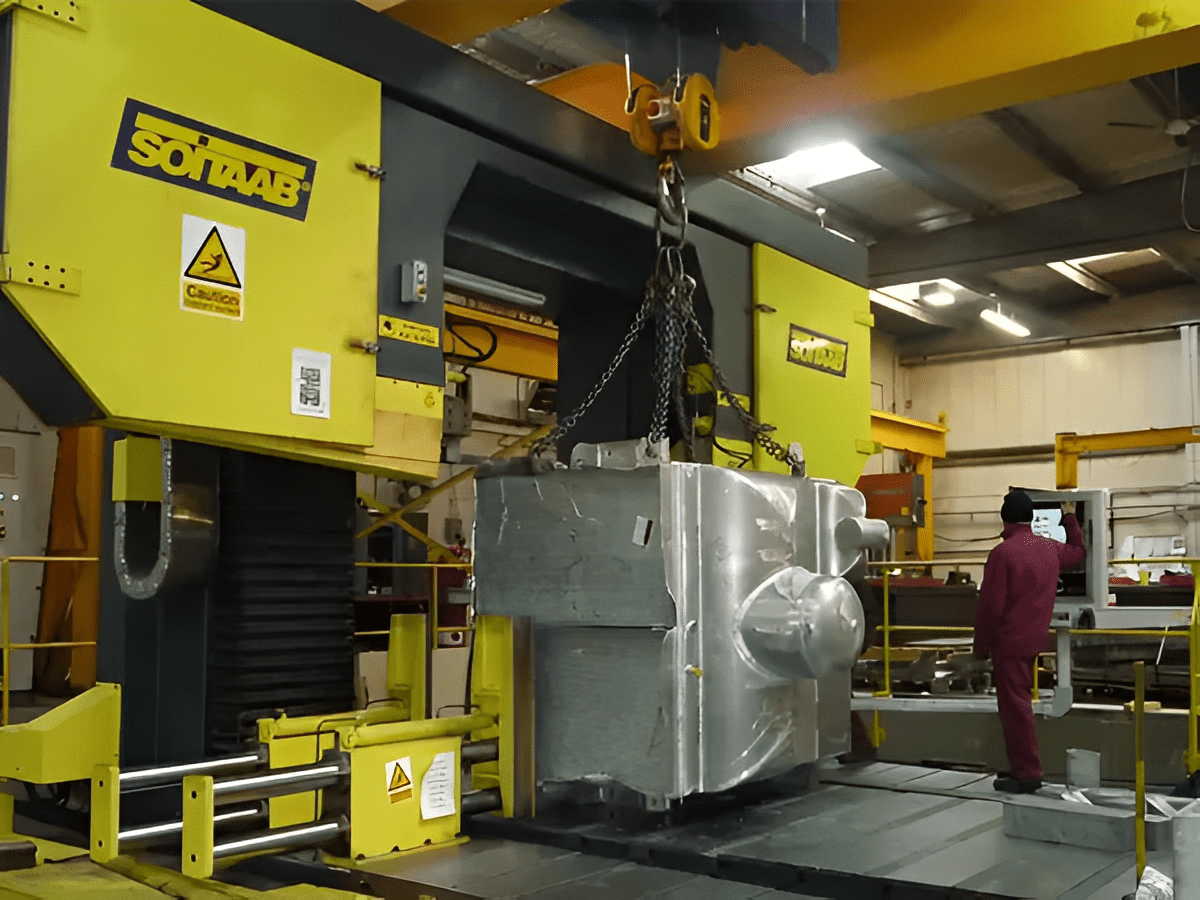

Even with the saw maximum capacities, we can often cut larger items depending on the particular cut to be achieved – contact our cutting office to discuss your requirement. Accurate Cutting Services can provide sawing solutions to a wide range of cutting problems, producing cost-effective answers where other techniques have failed.

Our sawing skills are founded on over 55 years’ actual sawing experience from a vast range of jobs with almost all metals used in manufacturing and in either as mill or finished machined forms. Our Midlands based saw shop can take most ferrous and non-ferrous metals, with sections from 12mm to 2000mm thick, and slab and plate up to 6000mm long, 1060mm thick and 25 tonnes in weight.

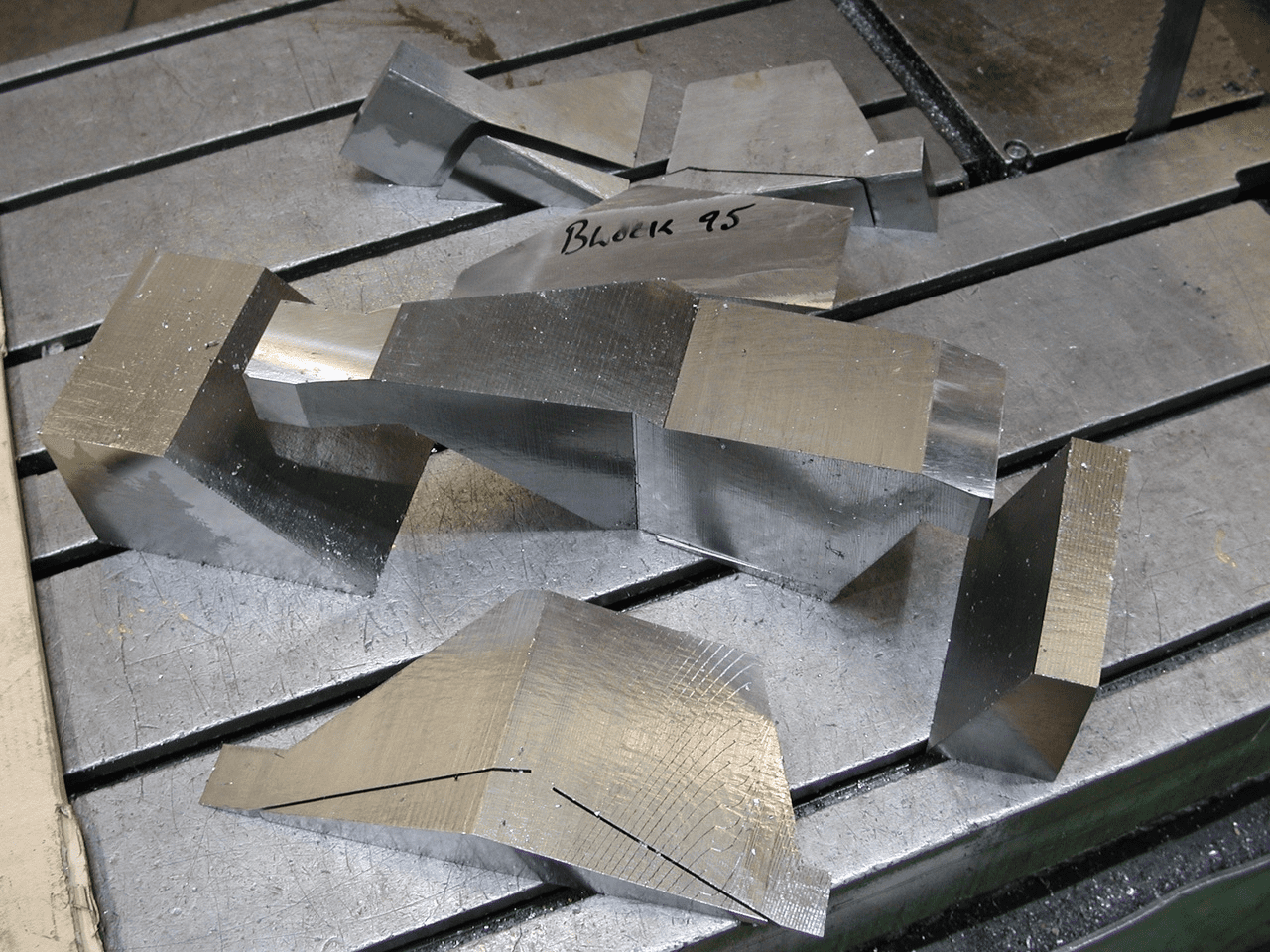

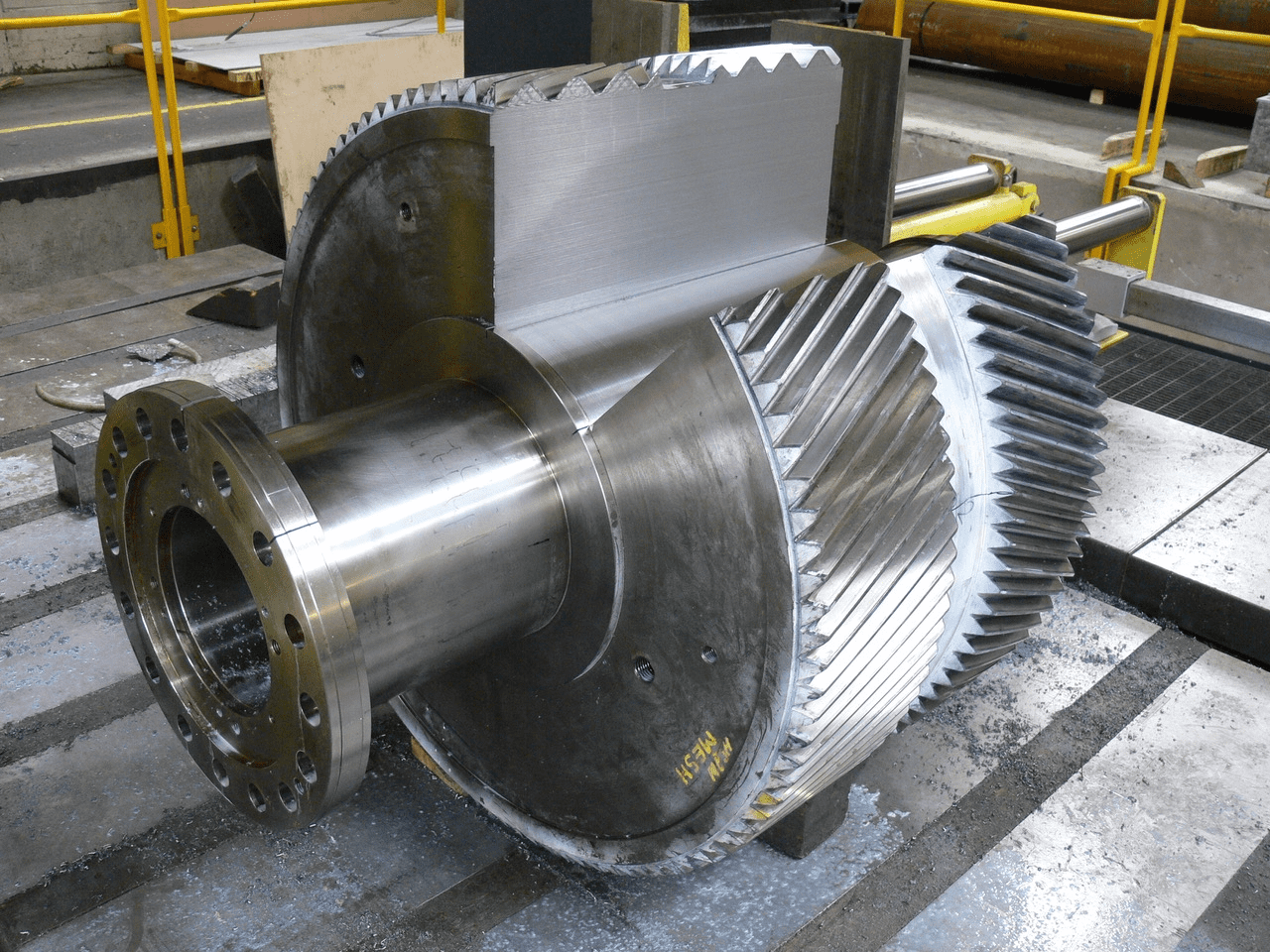

Profiling and sectioning

Large sawing capacity

Bandsawing to remove excess material

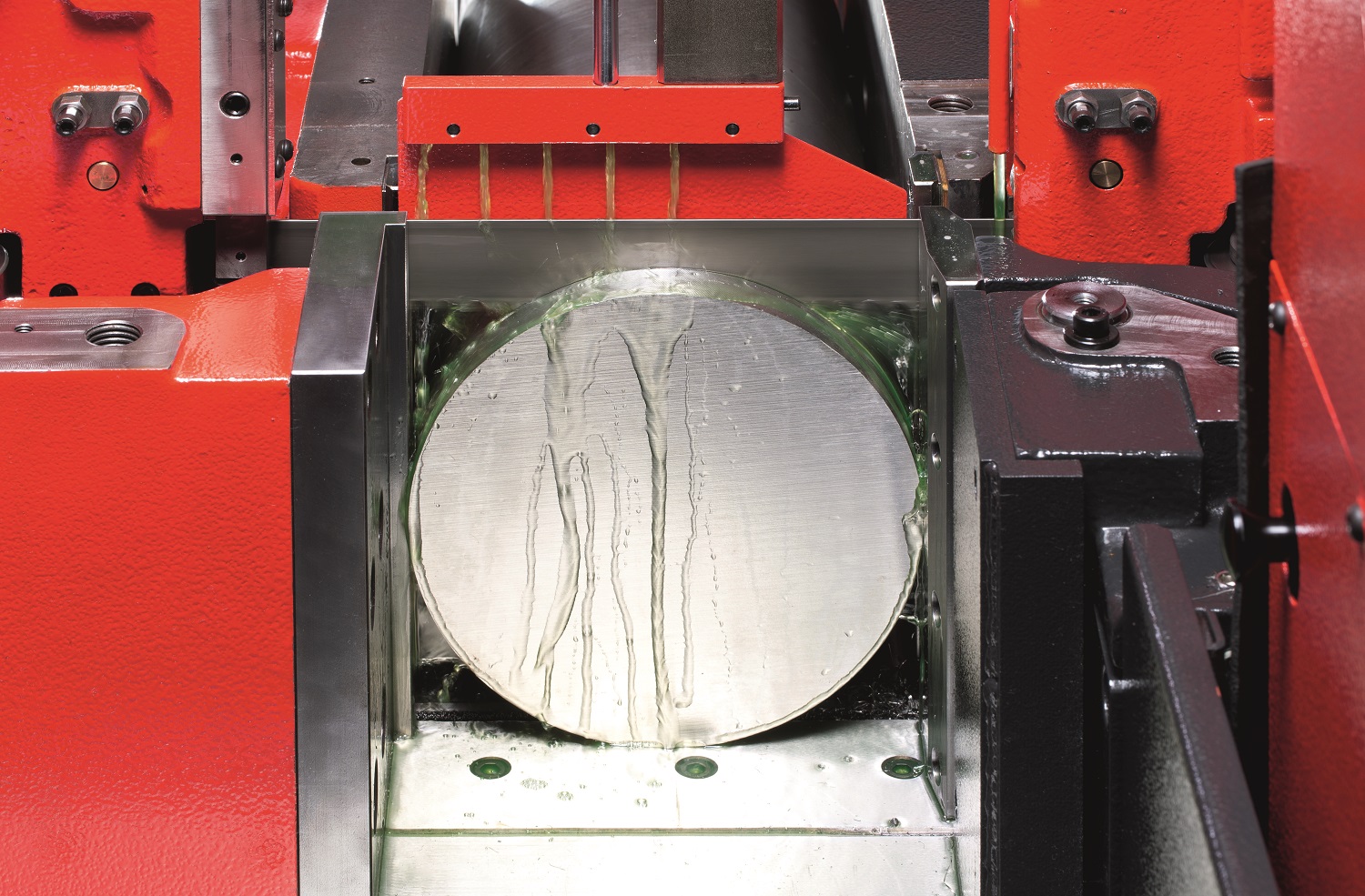

Precision metal cutting service

Reclamation and failure investigation using saws

Special cutting applications for saws

Materials

The company can work with and cut almost all machinable materials:

Aluminium; carbon and alloy steels; brasses; copper; aluminium and phosphor bronzes; aerospace and heat-resistant metals; stainless steels; matrix and metal composites; niobium; titanium and titanium alloys; zirconium; lithium.

It can saw non-metals also, including some engineering plastics.

Forms

The forms sawn are:

bar; tube; billet; block; slab; plate; castings; angle and structural sections; extrusions; forgings and fabrications; machines and part finished components.

| Best Tolerance | Commercial | |

| Billeting | from +/- 0.1mm for non-ferrous metals+/- 0.1mm up to 60mm dia, thereafter +/-0.25mm ferrous metals | +/- 0.25mm+/- 0.5mm |

| Plate | Â | +/- 3.0mm |

| Billet | from +/- 2.0mm on all dimensions | +/- 5.0mm |

ABOUT US

Our Quality Accreditation

Quality accreditation approvals EN 9100:2018 and ISO 9001:2015 The quality accreditation includes a system to provide lot traceability to raw materials/components operating within a Quality Management System, which complies with the requirements of pr EN9100:2016 (technically equivalent to AS9100D and JISQ 9100:2016) and ISO 9001:2015 and is assessed in accordance with EN 9104-001:2013.

Mitre and angle cutting capacity up to 2000mm (78″) round or square. Maximum weight limit 25 tonnes.

Contact us about our cutting capacity and capability.