Precision metal cutting service

Cost advantages from carbide circular sawing technology

Quality and cost advantages from the latest carbide circular sawing technology.

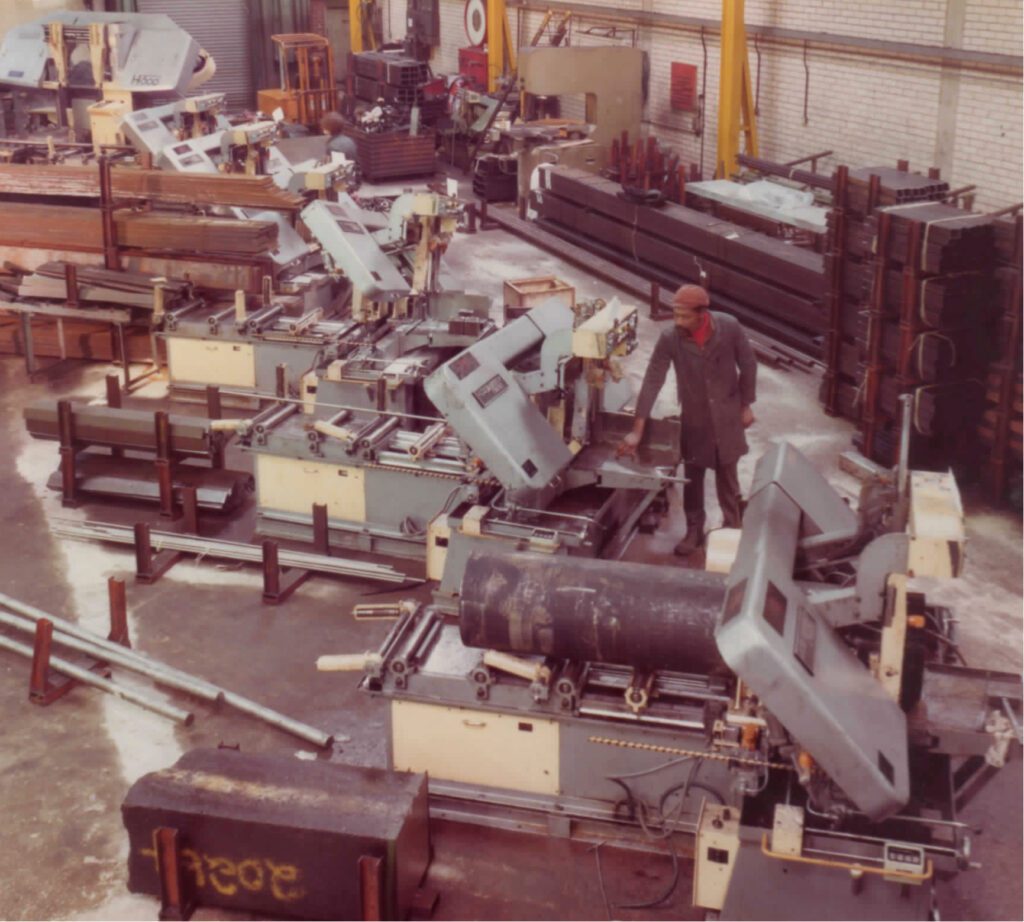

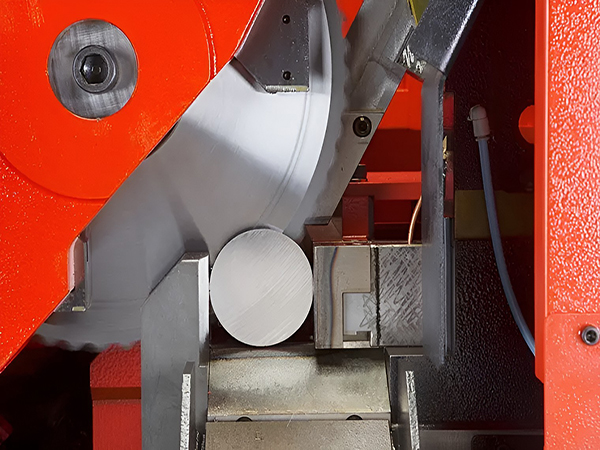

The Amada fully automatic carbide circular sawing machine (illustrated), using highspeed steel or tungsten carbide-tipped saw-blades, is one of several installed to produce high quality blanks for automotive component applications.

The basis for justification of a carbide solution is all about pieces on the floor. A carbide circular saw has a very high throughput of metal, at very high accuracy, and with a designed for purpose Amada disposable carbide blade, these saws out perform other solutions.

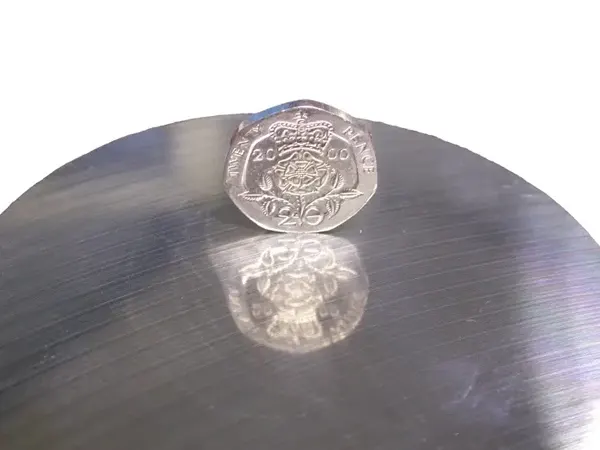

CNC control means that sawing conditions can be optimised, with output maximised. Close tolerance billets up to 0.25mm, (depending on material, size and blade wear) of up to 100mm diameter can be produced, in batch or volume quantities, using full Statistical Process Control if required. The accuracy of these saws provides a very accurate blank for cut-to-weight applications where the volume of material in a die is critical.

Carbide circular sawing cuts are virtually burr-free, with surface finishes so fine that further machining is often unnecessary.

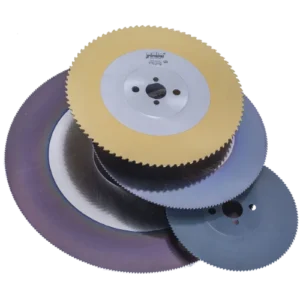

Specially designed carbide blade-tooth geometry gives these machines performance advantages compared to others. The blades are supported by carbide guides, on both sides of the blade body, to ensure that they remain true and square to the cut.

Components can be cut using oil mist lubrication, to produce virtually dry components with no adhering swarf.

Amada produce 4 variants of their carbide circular saws: