Carbide Bandsaw Blades

Carbide bandsaw blades for more specialised metal cutting applications, particularly for fast cutting rates in difficult to cut materials.

High-performance carbide bandsaw blades have a significantly higher cutting performance and increased life compared to standard bi-metal bandsaw blade when sawing solid sections, plate or slab and round or square bar in hardened and high-speed steels, tool steels, stainless steels, chrome nickel steels and nickel based alloys.

The ability to cut effectively, resisting high temperature at the tip, makes carbide tipped bandsaw blade an the ideal solution for high production bandsaws. The carbide tips are ground to precise geometries to provide a strong tooth edge and powerful chip removal qualities.

High quality body material is used to provide rigid support for the carbide tips whilst maintaining flexibility required as a bad running through guides and round wheels whilst resisting cracking and fatigue failure. The Amada bandsaw blades will cut faster and for longer than other bandsaw blades in most sawing applications.

As the only manufacturer of sawing machines and the saw blades, Amada can bring no-compromise performance through engineering of both critical elements for any metal sawing solution.

- Available in a range of tooth geometries to optimise performance for different material sections

- Various compositions of carbide used to suit sawn material types

- High cutting performance for maximum sawing performance

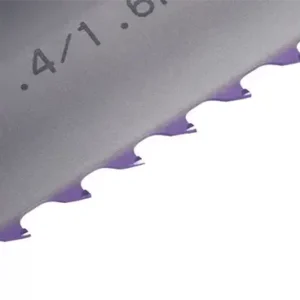

- Coated blades for maximum blade life through friction and tip wear reduction

- Performance body material to provide essential rigid support for the cutting tips with extremely low breakage

- Suitable for

- Cast iron

- Carbon and heat-treated steels

- All types of tool steels

- Hardening steels, spring and ball bearing steels

- Construction, deep-drawing and cutting steels

- Nitride and high-speed steels