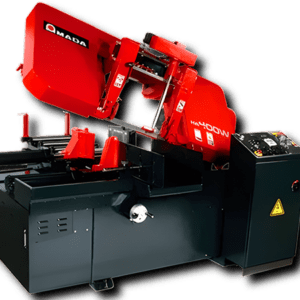

Amada HA250W automatic horizontal bandsaw

![]()

The Amada HA250W automatic horizontal bandsaw is a reliable workhorse industrial bandsaw machine designed around the capability of the saw blade, therefore guaranteeing optimum cutting performance.

Description

Amada HA250W automatic horizontal bandsaw

The Amada HA250W automatic horizontal bandsaw is a reliable workhorse industrial bandsaw machine designed around the capability of the saw blade, therefore guaranteeing optimum cutting performance.

Utilising a 34mm wide blade the Amada HA250W automatic horizontal bandsaw has sufficient beam strength to enable it to cut any metal quickly and efficiently, up to its maximum capacity of 250mm, thus delivering an excellent cost-per-cut ratio.

This simple robust bandsaw machine has often been imitated, however never surpassed.

Features

Pressure/flow feed control

The independent pressure and flow controls in series ensure that optimum cutting can be achieved regardless of the section or alloy being cut.

Drive wheel transmission

This is designed and built by Amada to provide high efficiency reduction, therefore delivering more power to the large diameter shaft. This ensures that developed torque is transferred to the blade.

Maximum cutting capacity

Round bar: 250 mm round bar

Rectangular bar: 300mm wide x 250mm high

Automatic, powered chip conveyor

Multiple index up to 9 times

Split front vice

Clamps the cut piece in front of the blade to reduce break-off tags.

Simple operation

Amada performance bandsaw blades

Saw service and spares

For larger capacity, see the Amada HA400W

Compact and robust completely automatic band saw machines in stable swivel joint design for economic cutting of solid, shaped and hollow materials in all material qualities including Inconel, Hastelloy and titanium – individually or in a bundle. In automatic operation, the cut-off length and piece count can be preselected.

The combined feed pressure system has the benefit of selecting the feed pressure according to the sawing task. For example, constant pressure for difficult to cut solid material, load-dependent feed for tubes and profiles.

Short cycle times due to patented material scanner with automatic changeover from rapid feed to feed. An integrated chip conveyor is included in the basic equipment.

The HFA models also have an automatic zero stop for material start detection.

The NC controller provides the requirement for automatic sawing using selectable cut-off lengths from 0 to 470 mm, with multiple infeed up to 9999 mm.

For a full specification, demonstration or quotation call now on 01274 870311